A Comprehensive Guide to Zebra Direct Thermal Vs. Thermal Transfer Labels for SMBs

Direct Thermal and Thermal Transfer Printers are a great choice for small business barcode label printing needs. More durable than other types of label printers, they operate reliably in both industrial and office settings. Zebra Technologies offers two types of thermal barcode printing—direct thermal and thermal transfer. Each offers unique advantages. Let’s look at how they compare, so you can choose the option that best meets your small business needs.

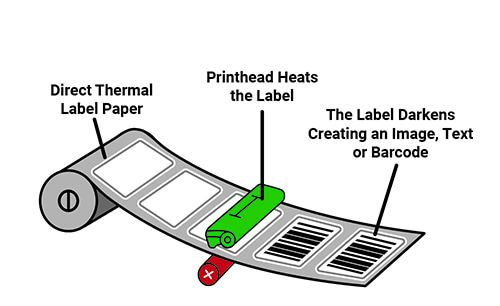

Direct Thermal Printing for Simplicity and Economy

Direct thermal printing is simple and economical because it prints without a ribbon, toner, or ink. Instead, it uses chemically treated, heat-sensitive media that blackens when it passes under the thermal printhead.

This thermal printing option is optimal for barcode printing applications requiring a short shelf life—such as shipping labels, patient and visitor identification, receipts, and ticket printing. Depending on use, the readability of direct thermal labels, wristbands, and receipt papers varies greatly. This option is not recommended for lifetime identification applications, because a direct thermal-printed label overexposed to heat or light will darken and make the text or barcode unreadable.

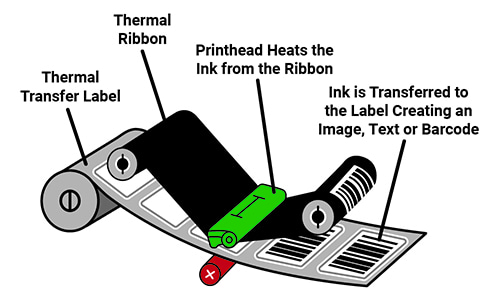

Thermal Transfer Printing for Enduring Readability and Scanability

Labels that are thermal transfer printed have a crisp, often glossy, surface. When heated by the printhead, a thin ribbon roll melts onto the label to form the image—absorbing the image into the media. This option offers unmatched readability and scanability with excellent edge definition—ideal for product labels and successful barcode printing and scanning.

When matched with the right media, thermal transfer technology is impervious to heat and moisture, and the image cannot be rubbed off. As a result, thermal transfer printed labels are the most durable available—withstanding temperature extremes, ultraviolet exposure, chemicals, sterilization, and more. This thermal print option is often well suited for product identification, circuit board tracking, permanent identification, sample and file tracking, asset tagging, inventory identification, cold storage and freezers, certification labels such as UL/CSA, laboratory specimens, and outdoor use.

Make the Right Thermal Printing Choice for Your Business

Want greater simplicity, lower costs, and short-term or indoor use? Direct thermal printing is likely to serve you best. Want higher-quality resolution and greater durability in any climate? Thermal transfer printing could be the way to go. This quick comparison chart can help you review the advantages of each option. Let’s break it down for you!

Direct Thermal

- Does not require a ribbon, for optimal simplicity but lesser durability.

- Chemically treated, heat-sensitive media passes under thermal printhead to image.

Simpler

- Easier to load

- No ribbon wrinkle or ribbon drive adjustments

- No need to pair ribbon to labels

Less Expensive

- No ribbon costs

- No need to manage SKUs

Ideal for Indoor & Short-Term Printing

- Use for applications requiring a short shelf life: shipping labels, receipts and name tags

Environmental Economy

- Recyclable materials available

Thermal Transfer

- Requires a ribbon to produce longer-lasting images on a wide variety of materials.

- Printhead applies heat to the ribbon to transfer images.

More Complex

- To obtain optimum print quality, ribbon and media substrate must be compatible

Exceptional Quality

- Suitable for professional print with excellent resolution, sharpness, and clarity

- Ribbons increase costs; however, thermal transfer printheads last longer than direct thermal printheads

Ideal for Outdoor & Permanent Printing

- Wide selection of materials for the most rugged environments

- Can be exposed to extreme temperatures, liquids, and chemicals

- Use for durable applications: product identification, inventory labels and asset labeling

Less Eco-Friendly

- Thermal transfer ribbon is not recyclable

Start Making the Right Label Choices Today

Advanced Automation makes it easy for you to explore Zebra solutions to meet your label printing objectives. We’ll help you choose the thermal printer that optimizes value and results for your small business.

Contact Our Barcoding Experts Today!

Related Article: Introducing the All New MC9400 / MC9450 Ultra-Rugged Mobile Computer

To learn more about Advanced Automation and the many services we offer. >> Click Here

339 SW 6th Street, Des Moines, IA 50309

www.advanced-automationinc.com